Thinking about getting a mobile health or wheelchair accessible vehicle? Then you’ve probably asked yourself this question—should it be built with aluminum or wood?

While both materials have their uses, aluminum is often the better choice due to its durability, moisture resistance, and lower maintenance needs. But what makes it better for mobile medical units, and are there situations where wood might still be considered?

The last thing you want is a vehicle that needs constant repairs or can’t keep up with your busy schedule. We know it’s easy to feel overwhelmed when making this choice. After all, if you’re running a mobile clinic, it should be ready to serve communities across Canada for years, not spend time stuck in the shop.

At MoveMobility, we build mobile health and accessible vehicles designed to bring healthcare and transportation to people who need it most. We’ve spent over 20 years helping Canadian organizations like yours and Main Street Project find solutions that work. While we know we’re not the only company out there, we’re here to share what we’ve learned so you can make the best decision for your medical or transportation program.

In this article, we’ll look at aluminum and wood, compare their pros and cons, and help you figure out which material is the best fit for your mobile health unit or wheelchair van.

Why do materials matter so much in mobile health and wheelchair accessible vehicles?

When it comes to mobile health and wheelchair accessible vehicles, the materials used to build them aren’t just about looks—they’re about performance and durability. Think about Canada’s weather. A vehicle operating in Vancouver might face constant rain, while one in Winnipeg has to handle freezing temperatures and heavy snow. So, can the materials in your vehicle stand up to these conditions?

The answer? Absolutely—they need to. Weather and temperature changes can affect how long your vehicle lasts and how well it performs. That’s why working with a manufacturer that understands Canada’s climate is so important. The right materials keep your vehicle:

Reliable: Hot summers in Ontario and icy roads in Alberta demand a vehicle that’s tough enough to handle any condition.

Comfortable: Patients and staff need a space that stays warm in the winter and cool in the summer.

Long-lasting: Durable materials mean fewer repairs, saving you time and money.

What makes the right materials so important?

The right materials for your unit can make a big difference in:

Safety: Smooth, sturdy surfaces help create a safe space for staff and patients, no matter the setting.

Energy efficiency: Insulated materials keep the temperature steady, so you don’t need to overwork heaters or air conditioners.

Low maintenance: Materials that resist damage mean fewer headaches and lower repair costs.

Durability: Strong materials stand up to Canada’s tough weather—from rainstorms to snowfalls—without warping or rusting.

When setting up a mobile medical clinic or a wheelchair accessible vehicle, it’s essential that the materials can withstand constant travel and heavy use. Now that you know why materials matter, let’s take a closer look at wood and see how it performs in mobile vehicle designs.

Can manufacturing mobile health and wheelchair accessible vehicles with wood cause problems?

Thinking about using wood in your mobile health or wheelchair accessible vehicle? It might seem like a budget-friendly option at first, but it can lead to bigger problems later on—especially if your vehicle is travelling across Canada’s unpredictable weather. The damp coastal air in Halifax and freezing winters in Edmonton can both lead to wood not holding up the way you’d hoped.

What problems can wood cause?

It doesn’t handle moisture well: If your vehicle spends time in rainy or humid areas, wood can absorb water and start to swell or rot. Over time, this can lead to mould, which is tough to fix and unsafe for a healthcare setting.

Cracks and splits over time: Wood expands and contracts as temperatures change, which can cause cracks. These cracks might not seem like a big deal at first, but they can weaken the structure and create gaps that let in moisture or pests.

It’s heavier than other materials: Wood adds weight to your vehicle, which can lead to higher fuel costs. That’s a big deal if your vehicle covers long distances, like heading to remote communities in Northern Ontario or rural Manitoba.

Fire risks: Since wood burns easily, it’s not the safest material for vehicles. When you’re running a mobile clinic or accessible unit, fire safety is something you can’t afford to overlook.

Harder to keep clean: Wood surfaces can scratch or chip, making them harder to sanitize properly. In a healthcare vehicle, where cleanliness is critical, this could be a major issue.

Is wood worth the risk?

While wood might cost less upfront, it often leads to more repairs, higher fuel costs, and safety concerns down the road. For vehicles that need to stay on the road for years—especially in Canada’s tough weather—materials like aluminum tend to hold up better and need less maintenance.

Next, let’s talk about aluminum and why it might be a better choice for your mobile health or wheelchair accessible vehicle.

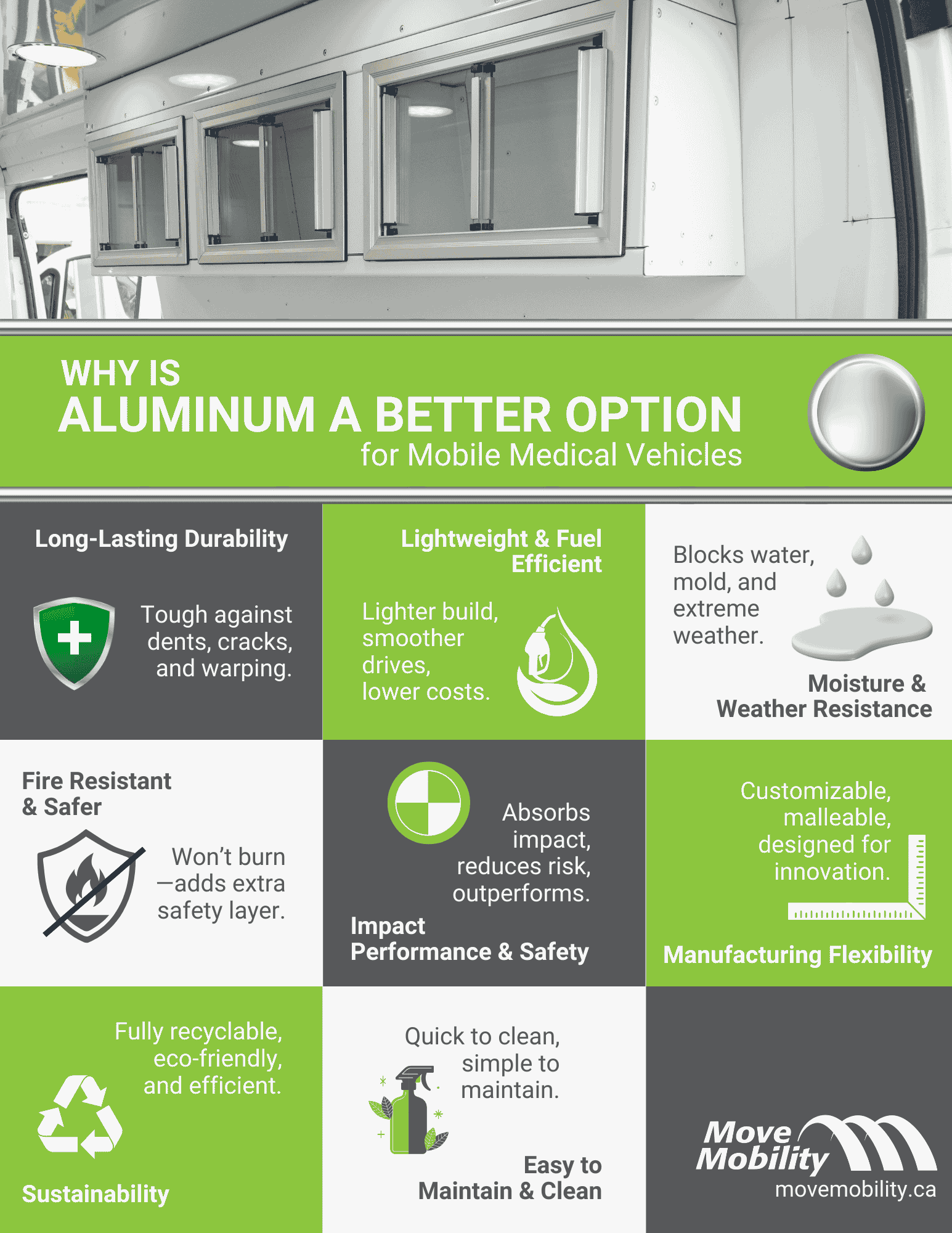

Why is aluminum a better choice for mobile health and wheelchair accessible vehicles?

When it comes to building mobile health and wheelchair accessible vehicles, aluminum is often the go-to material—and it’s easy to see why. Aluminum is built to handle Canada’s weather conditions, whether your vehicle is travelling through snowy highways in Quebec or rainy streets in Vancouver.

Key benefits of aluminum construction:

Long-lasting durability. Aluminum is strong and built to last. It resists dents, cracks, and other damage from bumps and rough roads, making it perfect for vehicles that need to stay on the move. Unlike wood, it won’t warp or rot if it’s exposed to moisture, so it’s a great fit for Canada’s wet and cold weather.

Lightweight design: Aluminum is much lighter than wood, which means your vehicle is easier to drive and uses less fuel. If your mobile unit needs to travel long distances—like servicing remote areas in the Yukon or Northern Ontario—this can lead to big savings on operating costs.

Moisture resistance: Rain, snow, and humidity don’t stand a chance against aluminum. It won’t absorb water, so there’s no need to worry about mould, swelling, or rot. This is a huge plus in areas with wet climates, like the Maritimes.

Simple cleaning and maintenance: Keeping a healthcare environment clean is critical. Aluminum surfaces are smooth and easy to wipe down, making it simple to meet high sanitation standards. It’s also rust-resistant, so it needs fewer repairs and less upkeep compared to wood.

Fire safety: Aluminum doesn’t burn, reducing fire risks inside the vehicle. Safety is always a top priority in a mobile medical unit or wheelchair-accessible vehicle, and aluminum adds an extra layer of protection.

Choosing aluminum for your mobile health or accessible vehicle means fewer repairs, lower fuel costs, and better long-term performance. It’s durable, safe, and easy to maintain—giving you peace of mind that your vehicle can keep serving your community for years to come.

Up next, let’s take a deeper look at each material.

A closer look at aluminum vs. wood for mobile medical and accessible vehicles

When choosing materials for mobile health and wheelchair accessible vehicles, it’s important to compare aluminum and wood to understand their strengths and weaknesses. Here’s a comparison based on key factors:

| Criteria | Aluminum | Wood |

| Weight | Lightweight, improving fuel efficiency and making the vehicle easier to handle. | Heavier, which can increase fuel costs and make handling more difficult. |

| Maintenance | Low maintenance—resists rust, rot, and environmental damage. | High maintenance—requires regular care to avoid rot, warping, and pest damage. |

| Sustainability | Fully recyclable, reducing environmental impact and waste. | Renewable resource, but often requires more upkeep and has a shorter lifespan. |

| Strength | High tensile strength (150-400 MPa), providing strong structural support. | Lower tensile strength (40-80 MPa), limiting durability under stress. |

| Corrosion resistance | Excellent—forms a protective oxide layer that prevents rust and decay. | Poor—vulnerable to rot and decay, especially in wet or humid conditions. |

| Manufacturing flexibility | Highly malleable and weldable, allowing for versatile designs and modifications. | Limited flexibility—harder to shape or modify for custom designs. |

| Impact performance | Predictable deformation, providing better safety through crumple zones. | Brittle—more likely to splinter upon impact, reducing overall safety. |

Note: MPa (megapascal) measures material strength under pressure or stress.

Ensure your next mobile health or wheelchair accessible vehicle lasts

You probably came to this article wondering whether aluminum or wood is better for your mobile health or wheelchair accessible vehicle. Now that you’ve read through it, you’ve learned that aluminum is stronger, lighter, and easier to maintain than wood—making it a better choice for long-term use.

At MoveMobility, we understand how important it is to have a vehicle that’s safe, reliable, and ready to handle Canada’s changing weather. That’s why we focus on building vehicles with aluminum so they will last and keep your services moving forward.

We’re here to help you find the right solution for your needs. If you have questions or want to learn more, click the button below to talk to a mobility expert today.

Not ready to chat yet? No worries! Check out our other resources to learn more when you’re ready.

Start by watching our video on the five steps to starting a mobile clinic.

After that, check out the video below to get a better idea of what you can expect to be paying for a mobile medical or wheelchair accessible vehicle.